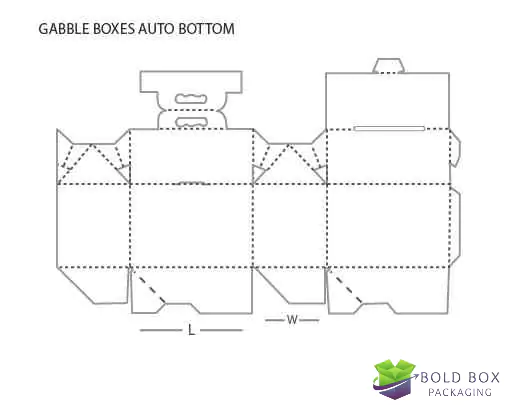

Businesses can save time and streamline their packaging process since the boxes require minimal assembly. This feature enhances efficiency, particularly in environments where quick turnaround is essential, such as bakeries packaging freshly baked goods or retail stores preparing products for display. Moreover, gable boxes with auto bottoms are designed for durability. The secure bottom ensures that the box maintains its shape and stability.

We have served 1000s of Happy Clients!

.jpg)

.png)

.png)

.png)

In retail settings, gable boxes with auto bottoms offer an elegant packaging solution for small electronics, cosmetics, or fashion accessories. The distinctive shape and customizable printing options allow businesses to create packaging that not only protects but also promotes their products effectively on store shelves. Gable boxes with auto bottoms are typically crafted from sturdy materials such as cardboard or paperboard. During production, a strong adhesive is applied to the bottom flaps of the box. This adhesive is activated when the box is folded into shape, automatically bonding the flaps together to form a secure bottom. The manufacturing process ensures consistency and reliability in the assembly of each box.

As sustainability becomes increasingly important, many manufacturers offer gable boxes with auto bottoms made from recyclable materials. Some are even biodegradable or compostable, aligning with eco-conscious practices and reducing environmental impact. Businesses and consumers alike can choose packaging options that support their sustainability goals without compromising on quality or functionality. The efficiency gained in packaging operations, coupled with the enhanced presentation and brand recognition, often outweighs the initial cost considerations.

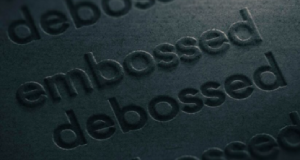

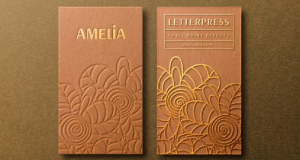

Customization options play a significant role in the appeal of gable boxes with auto bottoms. Businesses can personalize these boxes with their logo, brand colors, and promotional messages to create a distinct identity. Printing techniques such as matte or glossy finishes, embossing, or foiling further enhance the visual appeal and perceived value of the packaging. Customized gable boxes not only protect the product but also serve as a powerful marketing tool, leaving a lasting impression on customers. While gable boxes with auto bottoms may incur slightly higher costs compared to standard packaging due to their specialized features and customization options, many businesses find the investment worthwhile.

|

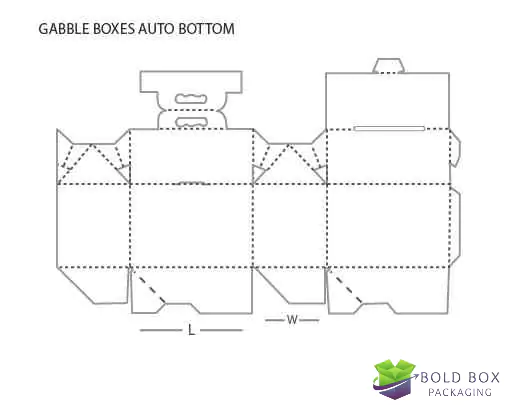

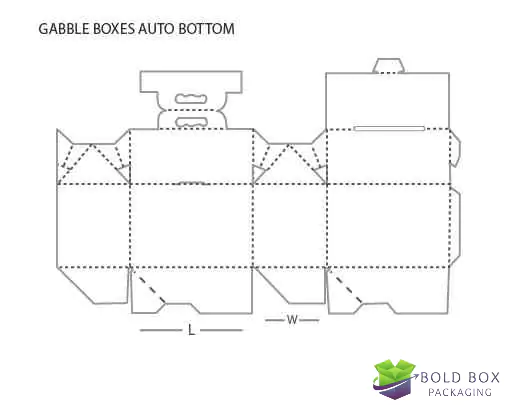

Specification |

Details |

|

Box Style |

Gabble Boxes Auto Bottom |

|

Dimension (L + W + H) |

All Custom Shapes & Sizes |

|

Quantities |

100 - 500,000 |

|

Stock |

10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

|

Printing |

No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

|

Finishing |

Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

|

Included Options |

Die Cutting, Gluing, Scored,Perforation |

|

Additional Options |

Eco-Friendly, Recycled Boxes, Biodegradable |

|

Proof |

Flat View, 3D Mock-up, Physical Sampling (On request) |

|

Turnaround |

4 - 8 Business Days, RUSH |

|

Shipping |

FLAT |

The first step is simple. You just have to fill out the form with your order requirements. Choose the product that you wish to purchase and fill out our quote form so that our team can get back to you with a free custom quote.

Our team gets back to you to discuss further on your project. If there is something that you might have missed in the form, you can communicate it with them directly. Once we have all your requirements, we start working on a quote which is then sent to you.

Our team explains to you everything about our manufacturing process while sharing the quote with you. The quote lists all the pricing along with our turnaround time. Once you agree to the quote, your order is placed and we can begin working on the manufacturing.

These boxes offer sturdiness which makes them suitable for a wide range of applications, from food packaging to retail products and gift presentations. The packaging solution has widespread use across various industries. In the food sector, they are popular for packaging items like pastries, cupcakes, and sandwiches. This provides a secure and hygienic packaging solution for takeaway or delivery.

It is often noticed in competitive market packaging that pops, grabs attention and become a source to inspire desire of consumers by boosting sales! This is all due to the standout features it possess: