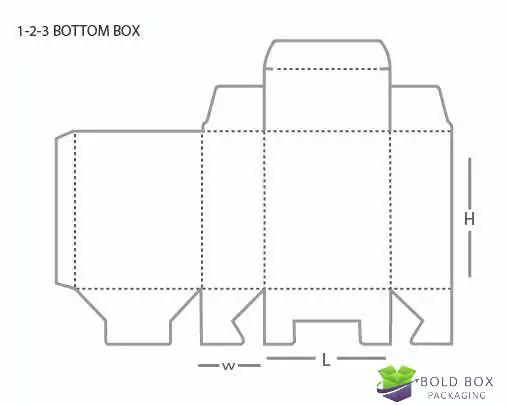

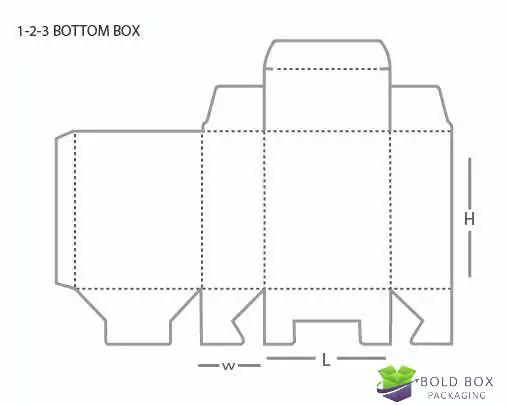

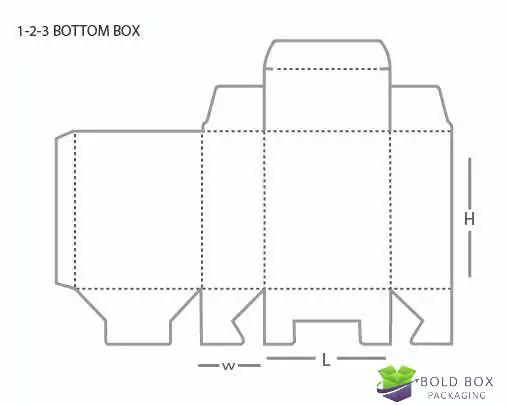

A 1-2-3 Bottom Box is a simple type of packaging. It's easy to put together because it has three flaps at the bottom. You fold these flaps in order: one, two, three, to make a strong base. These boxes are often used for packaging things like food, cosmetics, or small gadgets. They're convenient because you don't need tape or glue to assemble them.

We have served 1000s of Happy Clients!

.jpg)

.png)

.png)

.png)

The 1-2-3 Bottom Box is a widely used packaging solution for a range of small to medium-sized items such as cosmetics, electronics, or food products. Its nomenclature derives from the systematic way it's assembled: first, the bottom flaps are folded inward (1), then the side flaps are folded over (2), and finally, the top flaps are folded down (3). This straightforward assembly process not only ensures efficiency but also saves valuable time during the packaging phase, which can be crucial for businesses striving to meet tight deadlines or manage high-volume production schedules.

The appeal of the 1-2-3 Bottom Box extends beyond its assembly process; its robust design provides reliable protection for the items housed within. The interlocking bottom flaps create a secure closure mechanism, minimizing the risk of accidental spills or damage during transit. Moreover, these boxes offer a versatile canvas for branding and marketing efforts. Companies can leverage the ample surface area to print eye-catching designs, logos, or product information, effectively turning the packaging into a promotional tool that communicates brand identity and attracts consumer attention on store shelves or during online browsing.

From a business perspective, the advantages of utilizing 1-2-3 Bottom Boxes are manifold. Not only are they effective in safeguarding products during shipping and storage, but they also present a cost-effective packaging solution. Typically constructed from cardboard, these boxes are relatively inexpensive to manufacture, contributing to overall cost savings for businesses. Furthermore, their stackable design minimizes storage space requirements when flat. It optimizes warehouse efficiency and reduces associated overhead costs. With their combination of practical functionality, durability, and branding potential. Moreover, it's evident why the 1-2-3 Bottom Box remains a favored choice for packaging across diverse industries.

|

Specification |

Details |

|

Box Style |

1-2-3 Bottom Box |

|

Dimension (L + W + H) |

All Custom Shapes & Sizes |

|

Quantities |

100 - 500,000 |

|

Stock |

10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

|

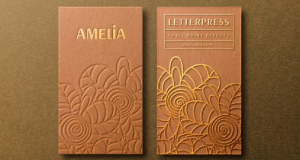

Printing |

No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

|

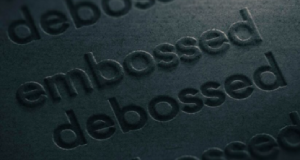

Finishing |

Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

|

Included Options |

Die Cutting, Gluing, Scored,Perforation |

|

Additional Options |

Eco-Friendly, Recycled Boxes, Biodegradable |

|

Proof |

Flat View, 3D Mock-up, Physical Sampling (On request) |

|

Turnaround |

4 - 8 Business Days, RUSH |

|

Shipping |

FLAT |

The first step is simple. You just have to fill out the form with your order requirements. Choose the product that you wish to purchase and fill out our quote form so that our team can get back to you with a free custom quote.

Our team gets back to you to discuss further on your project. If there is something that you might have missed in the form, you can communicate it with them directly. Once we have all your requirements, we start working on a quote which is then sent to you.

Our team explains to you everything about our manufacturing process while sharing the quote with you. The quote lists all the pricing along with our turnaround time. Once you agree to the quote, your order is placed and we can begin working on the manufacturing.

A 1-2-3 bottom box is a type of packaging that's easy to assemble. You fold the flaps in a specific order: first the side flaps, then the bottom flap. It's commonly used for shipping products like cosmetics, food items, and electronics. This box is sturdy and secure and protects during transport. Its design saves time and effort in packaging.

It is often noticed in competitive market packaging that pops, grabs attention and become a source to inspire desire of consumers by boosting sales! This is all due to the standout features it possess: